Heat Exchanger Design

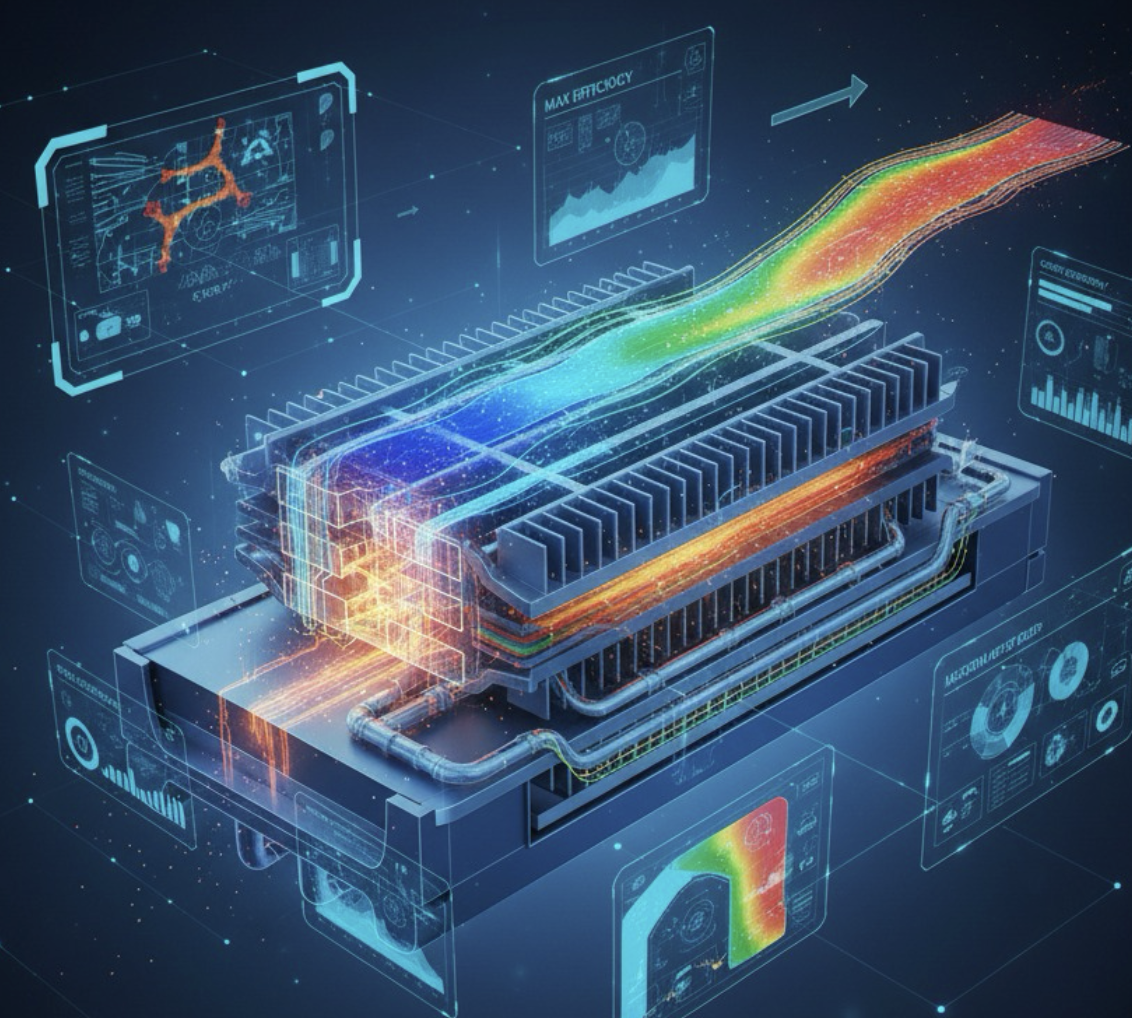

Our research on plate heat exchangers (PHEs) focused on numerical modeling, simulation, and optimization to improve their thermal-hydraulic performance for industrial processes and fuel cell thermal management systems. Using Computational Fluid Dynamics (CFD), we analyzed velocity and temperature fields under different Reynolds numbers and boundary conditions. Two design strategies were investigated: (1) optimizing the corner radius of channels to minimize flow separation and recirculation, and (2) introducing engineered surface roughness and stamped features to promote turbulence, disrupt boundary layer growth, and enhance heat transfer without excessive pressure loss.

Key Research Outcomes: • Achieved 7% increase in overall thermal effectiveness • Improved flow distribution uniformity by 25% • Reduced pressure drop by 12% through optimized geometry • Enhanced heat transfer coefficient by 15% using engineered surfaces • Developed new correlations for Nusselt number prediction

The integrated design improvements resulted in improved thermal uniformity and reduced risks of maldistribution and hot spots, particularly critical for fuel cell stacks. These findings demonstrate that geometry-driven flow management and engineered surface modifications can significantly enhance the performance of PHEs.